9 Best CNC Software for Beginners in 2025

Best CNC Software for Beginners: Welcome to the fascinating world of CNC machining, where digital design meets physical creation. If you’re reading this, you’re likely excited yet overwhelmed by the countless software options available for CNC machining. You might be a hobbyist, maker, or small business owner taking your first steps into computer numerical control technology.

This guide is here to help you navigate that maze. We will unravel the mystery surrounding CNC software, break down essential concepts such as CAD, CAM, and control, and provide clear, actionable advice on selecting the best software for your needs.

We aim to simplify this complex subject so you can make confident decisions that align with your project type, your machine’s compatibility, and your learning curve. In this guide, you will learn what CNC software does and why it is indispensable in turning your ideas into tangible products.

We’ll discuss everything from simple, web-based options to powerful desktop suites. Whether you’re planning to create intricate signs or complex three-dimensional components, this article will serve as your trusted roadmap. Prepare to dive deep, discover a world where creativity meets precision, and let your journey into CNC machining begin today!

What Exactly Is CNC Software (And Why You Need It)

CNC software is essentially the digital brain that translates your creative designs into precise instructions for your CNC machine. Simply put, it converts your digital drawings and 3D models into G-code, a language your machine understands and executes to cut, carve, drill, or mill your material. Without this intermediary, your computer-aided designs would remain just images on a screen.

Imagine you have a brilliant design for a custom sign or an intricate part. CNC software slices that design into layers, determining the best tool paths for your machine. By interpreting your design’s geometry and converting it into precise movement instructions, CNC software ensures that every cut is accurate and every turn is deliberate.

When you work with the right CNC software, you gain better control over the production process, reduce errors, and save valuable time. This software is a critical tool for professional manufacturing and a bridge that empowers hobbyists to bring their creative ideas to life. Understanding the role and capabilities of CNC software is the first step towards mastering your craft and ensuring your creative visions materialize with the utmost precision.

The Essential CNC Software Workflow: CAD, CAM, and Control Explained

Before you choose your first CNC software, it’s important to understand the complete workflow that transforms your ideas into physical objects. This journey starts with designing, moves through planning, and ends with machine control. Let’s break it down into three fundamental stages:

CAD: Designing Your Part

Computer-Aided Design (CAD) is where your creative vision begins. Think of CAD as your digital sketchpad. It allows you to design detailed 2D drawings or complex 3D models precisely. During this phase, you can experiment with shapes, dimensions, and intricate details without worrying about the physical limitations of your material. Here’s what CAD offers:

- Precision Drawing: Create accurate blueprints of your design.

- 3D Modeling: Build realistic models that capture every nuance.

- Editing Flexibility: Easily modify your design before committing.

- Visualization: View your creation from multiple angles.

- Compatibility: Save your design in various file formats suitable for further processing.

With the right CAD software, you set a solid foundation that influences every subsequent stage in your workflow.

CAM: Planning the Machining

Once you’ve perfected your design, it’s time to prepare it for the physical world using Computer-Aided Manufacturing (CAM) software. CAM is responsible for generating the tool paths that will instruct your CNC machine on how to cut, carve, or mill your material. Consider this phase as the plan that guides the craftsmanship of your design. Key functions include:

- Tool path Generation: Calculate the optimal routes for your cutting tool.

- G-code Creation: Convert your CAD files into G-code instructions.

- Simulation: Test the machining process virtually to spot potential issues.

- Tool Selection and Optimization: Determine your project’s best tools, speeds, and feeds.

- Adaptability: Tweak the machining strategy to accommodate different materials and design complexities.

Efficient CAM software minimizes waste, reduces machining time, and helps ensure that the final product is produced exactly as intended.

Control Software: Operating Your CNC Machine

The final stage of the workflow is the use of Control Software, which acts as the interface between your generated G-code and the physical motions of your CNC machine. This software is responsible for:

- Executing G-code: Reading and sending the correct commands to move the machine’s components.

- Machine Setup: Setting your machine’s starting point (zeroing) and calibrating the tool.

- Real-Time Monitoring: You can supervise the machining process and adjust as needed.

- Safety Controls: The ability to pause or stop the machine if an error occurs.

- Feedback Integration: Adjusting the process based on real-time performance data.

Control software is critical because, without it, you cannot accurately communicate your design’s complex instructions to the machine itself.

Integrated vs. Separate Software Solutions

Many modern CNC systems offer integrated solutions that combine CAD and CAM modules into one coherent platform, such as Easel or Fusion 360, while others may require separate control software like GRBL senders or LinuxCNC. Understanding whether a system is integrated or separate is crucial. An integrated system may simplify the learning process for beginners by providing a single interface to handle multiple tasks. However, separate systems might offer more advanced features and customization for professional production. Consider your immediate and future needs when deciding which solution to adopt.

How to Choose the Right First CNC Software: Key Factors for Beginners

Choosing the right CNC software is a personal decision. It depends on what you want to achieve, your level of technical comfort, your type of CNC machine, and even your budget. Let’s explore the key factors guiding you to the perfect software for your requirements.

What Will You Be Making? (Project Type Matters)

Before you select any software, ask yourself:

- Simple Projects vs. Complex Designs: Will you start with basic 2D signs or venture into detailed 3D carvings?

- Material Considerations: Are you working with wood, plastics, or soft metals? Different materials may demand different software capabilities.

- Engraving or Milling: Are you planning fine engravings or robust milling? Consider the level of detail and precision required for your projects.

Answering these questions helps you narrow down the software that offers the right balance of power and simplicity for your target project types.

Your CNC Machine & Its Controller (Compatibility is King)

Next, consider the specifics of your CNC machine. Different machines use different controllers and firmware, such as GRBL or LinuxCNC. Ensure that your chosen software can generate the appropriate G-code compatible with your machine’s requirements. Work out these crucial details:

- Firmware Compatibility: Confirm that the software supports the firmware running on your machine, be it GRBL, Mach3, or another system.

- Data Connection: Ensure your control software communicates flawlessly with your machine via USB or serial connections.

- Manufacturer Recommendations: Look for software endorsements by the makers of your CNC machine, as these often indicate smoother integration and setup processes.

Verifying compatibility at the start saves time and frustration during the operational phase.

Ease of Use vs. Power (The Learning Curve)

It’s essential to balance the power of the software with its ease of use. For a beginner, an overly sophisticated tool could be intimidating and counterproductive. When considering ease of use, reflect on:

- User Interface: Is the layout intuitive, or will you spend hours figuring out where things are?

- Step-by-Step Guidance: Does the software offer tutorials, wizards, and contextual help to guide you through the process?

- Progressive Learning: Can you master simple tasks before gradually exploring advanced functionalities?

- Community Support: Are there active forums, user groups, or customer service channels to help you overcome common challenges?

Remember, starting with a simpler program that enables you to understand the basics is perfectly fine. As your skills grow, you can gradually adopt more advanced features.

Your Budget: Free vs. Paid Options

A practical consideration in your decision-making process is your budget. Many high-quality, free software options are available that are more than sufficient for a beginner’s needs. Compare these factors when evaluating cost:

- Initial Cost: Many entry-level software packages are free or offer a free tier with essential features.

- Value Over Time: Paid software might provide additional tools and support that can streamline advanced projects.

- Trial Periods: Look for software that offers a trial period so you can evaluate its suitability for your projects without a financial commitment.

- Long-Term Investment: Consider whether the paid option might help you scale your capabilities as your business or skills evolve.

This upfront analysis ensures you don’t overspend while still accessing all the necessary features you need to start your CNC journey.

Community, Support, and Tutorials

Learning CNC software can be challenging, especially when navigating it alone. Active community support, comprehensive documentation, and abundant tutorials are invaluable. Check for the following:

- Active Forums: Many software providers have dedicated user communities where you can ask questions, share experiences, and receive troubleshooting advice.

- YouTube Tutorials: Visual aids can often simplify complex tasks. Look for channels and playlists that walk you through key steps and advanced techniques.

- Official Documentation: A well-documented manual or knowledge base can be a lifesaver when encountering unexpected hurdles.

- Customer Support: Consider the availability of direct support channels if you run into technical problems.

By choosing software that offers robust support and clear educational resources, you can significantly reduce your learning curve and eliminate unnecessary frustration.

Top 9 Best CNC Software for Beginners in 2025

Below, we provide an in-depth review of nine popular CNC software choices designed for beginners. Each software review includes a detailed overview, key features, pros, and cons. This information will help you decide which tool best meets your unique needs.

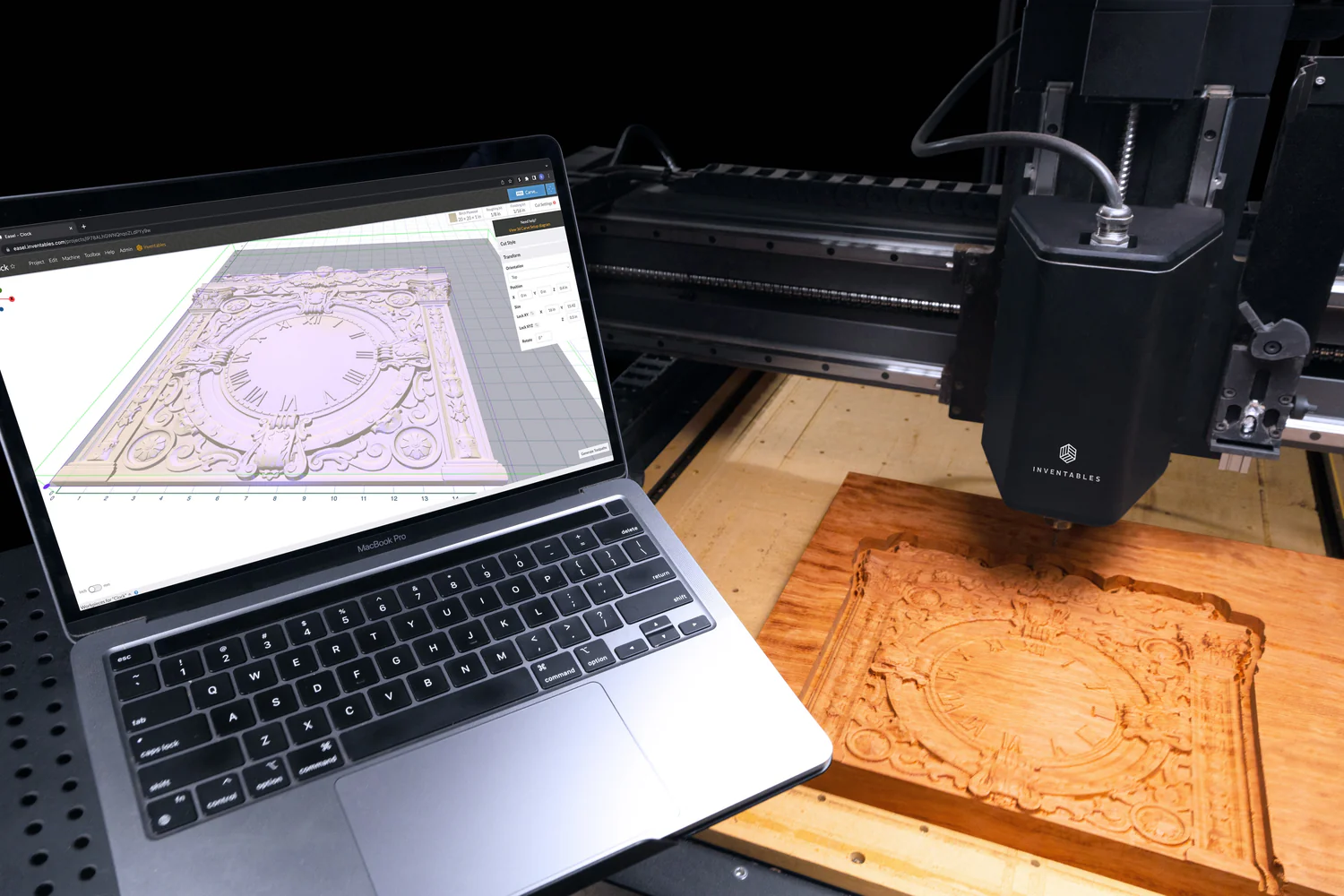

1. Easel by Inventables (Web-Based CAD/CAM)

Easel is a web-based CAD/CAM solution renowned for its simplicity and accessibility. It is tailored for beginners and offers an intuitive design and tool path generation interface, making it a perfect choice for basic 2D and 2.5D projects such as signs, cutouts, and carvings.

With a built-in object library and simulation features, Easel lets you see your design come to life before machining begins. Especially popular among users of Inventables’ X-Carve, it remains adaptable to various GRBL machines while offering a free tier that eliminates the steep learning curve for newcomers.

Key Features:

- Browser-based interface accessible from any device

- Intuitive design tools with drag-and-drop functionality

- Integrated object library for quick project setup

- Simulation mode to preview tool paths and potential errors

- Simple tool path customization for various materials

Pros:

- Extremely beginner-friendly and accessible

- The free tier provides robust functionality

- Seamless integration with Inventables’ X-Carve and other GRBL machines

Cons:

- Limited advanced design tools compared to desktop software

- Requires a consistent internet connection

- Pro subscription needed for more complex features

2. Carbide Create (Desktop CAD/CAM)

Carbide Create is a free desktop CAD/CAM program designed for hobbyists and small business users operating CNC machines such as Shapeoko and Nomad. Focused on 2D and 2.5D design, it simplifies creating precise designs and generating tool paths for various cutting projects.

With an easy-to-navigate interface and integrated simulation tools, Carbide Create enables beginners to explore CNC machining without the intimidation of overly complex software. An optional Pro upgrade further enhances capabilities with additional features for more advanced tasks.

Key Features:

- User-friendly desktop interface designed for ease of use

- Basic CAD tools optimized for 2D and 2.5D projects

- V-carving and texture tool path generation

- Simulation features to verify cutting strategies

- Optional Pro version for added functionality in 3D milling

Pros:

- Free to use for basic projects, making it budget-friendly

- Seamlessly integrates with Carbide Motion control software

- Offers offline accessibility for uninterrupted work

Cons:

- Limited 3D modelling and advanced CAM features in the free version

- It may feel basic for users who quickly outgrow simple designs

- The interface can be less modern compared to some web-based options

3. VCarve by Vectric (Desktop CAD/CAM)

VCarve by Vectric is a powerful desktop CAD/CAM suite specializing in intricate 2D and 2.5D designs, making it a favourite for serious hobbyists and professional users. Known for its detailed V-carving and engraving capabilities, VCarve excels in crafting detailed signs, sculptures, and artistic projects.

It features a comprehensive set of tools for vector drawing, texture mapping, and realistic simulation, which allow users to fine-tune their designs and tool paths precisely. Although it has a higher price tag, its robust performance offers excellent value for intensive projects.

Key Features:

- Extensive vector drawing and V-carving capabilities

- Multiple tool path options for precise cutting

- Integrated simulation to preview the machining process

- Supports conversion of both 2D and 3D designs for tool path generation

- Scalable software versions to accommodate various project sizes

Pros:

- Industry-standard software for quality, detailed work

- Excellent support and extensive user community

- Robust simulation and tool path options for professional results

Cons:

- High cost may limit accessibility for absolute beginners

- It can be overly feature-rich for simple projects

- Different software editions can create confusion for newcomers

4. Carveco Maker (Desktop CAD/CAM)

Carveco Maker is a subscription-based desktop CAD/CAM solution strongly emphasizing creative artistry. With roots in the advanced technology of ArtCAM, Carveco Maker caters to users focused on artistic CNC projects such as woodworking, jewellery design, and intricate signage.

It offers powerful relief modelling tools and advanced vector drawing capabilities that enable users to create detailed, sculptural effects. Although its complexity may initially seem daunting to absolute beginners, the integrated workflow and regular subscription updates empower creative users who are ready to invest time in evolving their skills.

Key Features:

- Advanced 3D relief modelling and sculpting tools

- Robust vector drawing and texturing options

- Integrated workflow that connects design to tool path generation

- Multiple strategies for generating optimized tool paths

- Regular software updates through subscription packages

Pros:

- Exceptional artistic capabilities for creative projects

- Integrated workflow reduces setup time for complex designs

- Regular feature updates keep the software current with industry trends

Cons:

- Subscription fees can increase overall costs over time

- A steeper learning curve for users focused solely on simple cuts

- Complexity may deter beginners interested in straightforward tasks

5. Autodesk Fusion 360 (Cloud-Based CAD/CAM/CAE)

Fusion 360 by Autodesk is a cloud-based integrated CAD/CAM/CAE platform for professionals and hobbyists. It offers a comprehensive suite of tools ranging from parametric 3D modelling to advanced simulation and dynamic tool path generation.

It is ideal for complex and multi-axis machining projects, Fusion 360 permits collaborative engineering and real-time project sharing. Although its extensive feature set comes with a steep learning curve, its free personal use license makes it accessible to those looking to develop industry-relevant skills while working on sophisticated designs and production projects.

Key Features:

- Parametric 3D modelling and dynamic design tools

- Advanced CAM features supporting multi-axis operations

- Real-time simulation and stress analysis

- Cloud collaboration and secure project sharing

- Seamless integration with various design formats and hardware

Pros:

- Exceptionally powerful and versatile for diverse projects

- Free personal license opens opportunities for hobbyists

- Widely used in professional environments for transferable skills

Cons:

- A steep learning curve may overwhelm beginners

- Cloud-based workflows require a stable internet connection

- The free license comes with limitations and frequently changing terms

6. FreeCAD (Desktop Open-Source CAD/CAM)

FreeCAD is a free, open-source, parametric 3D modeller offering a dedicated CAM workbench as part of its modular system. FreeCAD allows you to easily create, modify, and revisit your models, ideal for users committed to open-source software and customization.

Its flexible architecture supports various workflows, including the Path Workbench for CAM processes, making it a versatile tool for both design and machining. Although it has a steeper learning curve in certain modules, its endless customization possibilities empower dedicated DIY enthusiasts and professionals.

Key Features:

- Parametric 3D modelling with extensive edit history

- Modular architecture with specialized CAM (Path Workbench)

- High customizability through community-developed add-ons

- Completely free with no licensing fees

- Supportive, active, open-source community and documentation

Pros:

- Completely cost-free, ideal for budget-conscious users

- Powerful and flexible design capabilities

- Highly customizable with a wealth of community add-ons

Cons:

- The CAM workbench can be less intuitive than commercial software

- Interface may feel outdated compared to modern suites

- A steeper learning curve, particularly in advanced modules

7. GRBL (Firmware & Ecosystem)

GRBL is the open-source firmware that runs on CNC controller boards, typically Arduino-based, powering countless hobby and DIY CNC machines. Rather than being a complete design suite, GRBL focuses on interpreting G-code and controlling machine movements with high precision.

To use GRBL effectively, it must be paired with a compatible “G-code Sender” software, which allows you to upload and run your machining projects. Praised for its reliability and efficiency, GRBL remains a popular choice in the maker community for powering cost-effective, custom-built CNC setups.

Key Features:

- Provides efficient real-time motion control for 3-axis machines

- Interprets standard G-code with high precision

- Open-source framework for custom modifications

- Widely supported by a vast ecosystem of G-code sender programs

- Lightweight and optimized for Arduino-based CNC controllers

Pros:

- Ubiquitously adopted by hobby CNC machine builders

- Reliable and proven in numerous applications

- Completely free and highly adaptable to various setups

Cons:

- Functions solely as firmware; requires pairing with sender software

- It does not provide graphical design or CAM capabilities

- Basic configuration may require some technical know-how

8. LinuxCNC (Desktop Control Software & OS)

LinuxCNC is an open-source software suite that transforms a standard Linux-based PC into a full-featured CNC machine controller. Designed for advanced users and custom machine builds, LinuxCNC offers real-time motion control, configurable kinematics, and even PLC ladder logic for automation.

While it demands a dedicated PC running Linux and extensive configuration, LinuxCNC provides unparalleled flexibility and power for those who need to push the boundaries of their machining projects. It is especially suitable for retrofitting older machines or building custom CNC platforms.

Key Features:

- Real-time motion control with a dedicated Linux operating environment

- Highly configurable for various machine setups and kinematics

- Integrated PLC ladder logic for automation and complex sequences

- Open-source with a vibrant community and extensive documentation

- Supports multiple machining strategies tailored to unique projects

Pros:

- Extremely powerful and flexible for custom applications

- Completely free with advanced control capabilities

- Ideal for users comfortable with Linux and technical setups

Cons:

- Requires dedicated hardware and expert-level setup

- The steep learning curve for users unfamiliar with Linux

- Complex configuration may not suit plug-and-play needs

9. Kiri:Moto (Web-Based CAM)

Kiri:Moto is a browser-based CAM tool offering a streamlined, web-accessible solution for generating basic tool paths and G-code. Supporting CNC, laser cutting, and even 3D printing workflows, Kiri:Moto provides flexibility for users exploring multiple fabrication methods.

A clean interface and quick setup let you convert designs into machinable code in real time. Although it may not have the full range of features offered by comprehensive desktop CAM software, Kiri:Moto is a lightweight, accessible option ideal for beginners and those looking for a fast, online tool.

Key Features:

- Web-based interface that runs on any modern browser

- Supports multiple fabrication processes: CNC, laser, and 3D printing

- Rapid conversion of designs into G-code tool paths

- Simple user interface tailored for quick learning and integration

- Requires no installation, making it highly accessible on the go

Pros:

- Completely free with minimal setup requirements

- Versatile in supporting a variety of manufacturing methods

- Ideal for basic tasks and quick tool path generation

Cons:

- There are fewer advanced features than dedicated desktop CAM software

- Dependent on a stable internet connection for optimal use

- May not manage complex machining strategies as effectively

Making Your Final Choice: A Quick Decision Tree for Beginners

Selecting the right CNC software can be daunting, so here’s a simple decision tree to guide you:

- Are your projects simple 2D or 2.5D creations (like signs and cutouts)?

- If yes, start with an easy-to-use, beginner-friendly solution like Easel or Carbide Create.

- Are you planning to create intricate artistic carvings or detailed engravings?

- Consider advanced options such as VCarve or Carveco Maker tailored for artistic projects.

- Do you need advanced 3D modelling and multi-axis machining capabilities for engineering designs?

- In this case, explore Autodesk Fusion 360 for its integrated CAD/CAM/CAE powerhouse.

- Are you an open-source enthusiast who enjoys customizing your tools?

- Then FreeCAD might be the right choice, provided you’re prepared for its modular learning curve.

- Is your focus only on machine control for a GRBL-based setup?

- Opt for GRBL, paired with a reliable G-code sender, to manage your machine efficiently.

- Do you plan to build or retrofit a custom CNC machine, and are you comfortable with Linux?

- LinuxCNC offers robust, advanced control with high flexibility.

- Need a lightweight, online CAM tool for quick projects?

- Kiri:Moto is a fast, web-based option that might suit your immediate needs.

Mapping your priorities will ensure you choose the software that best suits your project type, machine compatibility, and budget.

Don’t Panic! Tips for Learning Your Chosen CNC Software

Beginning your journey with CNC software can feel like stepping into a new technical realm. Here are some tips to help you along the way:

- Start with the Basics:

- Focus on mastering one function at a time. Get comfortable with the software’s interface before diving into advanced features.

- Leverage Official Resources:

- Utilize the tutorials, webinars, and documentation provided by the software creators. These resources are designed to help you get started quickly.

- Watch Video Tutorials:

- YouTube and other video platforms offer step-by-step guides that can make complex procedures easier to understand.

- Participate in Community Forums:

- Engage with fellow users. Online communities and discussion groups are full of people who have faced similar challenges.

- Practice on Test Projects:

- Start with small, low-cost projects. Practice using foam or scrap material before committing to expensive materials.

- Document Your Process:

- Keep notes on your workflow and any shortcuts you discover. A personal guide can save time in the future.

- Be Patient and Persistent:

- Mastery does not come overnight. Celebrate small wins, and don’t get discouraged by initial setbacks.

Following these tips will accelerate your learning and boost your confidence as you gain proficiency with your chosen CNC software.

Conclusion

Choosing the right CNC software is more than just a technical decision; it is a step towards unlocking your creative potential. As you progress from simple projects to complex designs, the skills you build will serve as the backbone of countless innovative creations. The landscape of CNC machining is vast and full of opportunities. Each step you take in mastering your software is a step towards achieving precision, efficiency, and artistic excellence. Remember, every expert started as a beginner, and your willingness to learn and experiment will eventually make you proficient in translating your digital visions into tangible reality.

Keep exploring, stay curious, and enjoy every moment of your CNC journey. With the right tools and a community of makers behind you, nothing can stop you from discovering a niche that reflects your passion and creativity.

Now that you understand CNC software and the best options for beginners, it’s time to take action. Download a free trial or free version of the software that excites you the most, and start exploring its features today. Join online forums and subscribe to our newsletter for regular updates and tips on CNC machining.

Share your journey with us in the comments below. Tell us which software you chose and why. Embrace the challenge and let your creativity guide you to success. Happy machining, and welcome to the exciting world of CNC!

We invite you to bookmark this guide, share it with fellow makers, and continue your quest for knowledge in the ever-evolving world of CNC machining. Here’s to countless hours of creativity and innovation your CNC adventure awaits!

Frequently Asked Questions (FAQ)

Can I Use Just One Program for Everything (Design, Tool Paths, Control)?

Many integrated solutions combine CAD, CAM, and some control functionalities into a single software package. However, even with tools like Fusion 360 or Easel, you might still need a separate control program (like a GRBL sender or LinuxCNC) to run your machine. Integrated systems simplify the process, but dedicated control software is often necessary for full control and flexibility.

Do I Always Need an Internet Connection to Use CNC Software?

Not necessarily. While web-based tools like Easel and Kiri:Moto require an internet connection, most desktop applications such as Carbide Create, VCarve, Fusion 360 (which can operate offline after syncing), FreeCAD, and LinuxCNC do not. Additionally, control software typically functions independently of internet connectivity.

What’s the Easiest Software to Begin With for Cutting Simple Shapes?

Easel and Carbide Create are often recommended for beginners focusing on basic 2D or 2.5D projects. Their streamlined interfaces and intuitive tool path generation capabilities make them ideal for newcomers who want to see quick results without a steep learning curve.

How Much Should I Spend on Beginner CNC Software?

It’s possible to start with little to no investment. Many excellent options, such as Easel (free tier), Carbide Create, FreeCAD, Kiri:Moto, and open-source GRBL sender programs, are available at zero cost. More advanced solutions like VCarve or Carveco Maker come at a premium, so consider your current needs and long-term plans before committing financially.

How Do I Know if the Software I Choose Will Work with My CNC Machine?

Compatibility is key. Always check that the software outputs G-code that matches your machine’s firmware (e.g., GRBL) and that your control software can effectively communicate with your CNC hardware. Consult manufacturer documentation and community forums to gather insights about your machine model.

What is CNC software for beginners, and why is it important?

CNC software for beginners refers to digital tools that transform your design concepts into machine-readable G-code. These programs simplify complex processes by integrating CAD (design) and CAM (machining) functionalities, enabling you to create, simulate, and execute projects effectively. They are tailored to be user-friendly and come with plenty of tutorials and community support. Employing such software is crucial as it bridges the gap between your ideas and finished products, making your entry into CNC machining smoother and more enjoyable.

How do I choose the right CNC software for beginners?

Choosing the right CNC software for beginners requires balancing ease of use with functionality. Consider a tool’s interface and the availability of learning resources such as tutorials, community forums, and documentation that suit your comfort level. Evaluate if the software offers integrated CAD/CAM features and is compatible with your CNC machine’s firmware (like GRBL). Free trials and free versions are excellent starting points that allow you to test the features without an initial financial commitment, ensuring a smoother learning curve.

What are the primary features I should look for in CNC software for beginners?

When selecting CNC software for beginners, look for features that simplify design and machining processes. Key attributes include an intuitive interface, built-in tutorials, and integrated simulation modes that let you preview tool paths. The software should seamlessly combine CAD and CAM capabilities, manage basic 2D/2.5D projects, and offer compatibility with common CNC controllers. These essential features ensure that you can easily learn and gradually progress to more complex projects, making your entry into CNC machining a hassle-free experience.

Can free CNC software for beginners deliver quality performance?

Absolutely, free CNC software for beginners often delivers excellent performance. Many free programs provide comprehensive CAD/CAM functionalities ideal for hobby projects and initial experiments. They typically include user-friendly design tools and basic simulation capabilities and generate accurate G-code without a steep learning curve. While they might not have the advanced features of paid software, these free tools are perfectly suited for beginners looking to build foundational skills and create simple projects before transitioning to more advanced platforms if needed.

Are web-based CNC software for beginners as effective as desktop applications?

Web-based CNC software for beginners can be as effective as desktop applications, particularly for those starting out. They offer accessibility from any computer with an internet connection and feature intuitive, streamlined interfaces designed to minimize complexity. While web-based options excel at facilitating basic 2D and 2.5D projects, desktop applications may offer more advanced features as your skills grow. Both types provide effective solutions, so selecting between them depends on your work habits, internet reliability, and specific project requirements.

How do integrated systems differ from separate control solutions in CNC software for beginners?

Integrated CNC software for beginners combines design (CAD) and machining (CAM) functions into a single package, simplifying the workflow by eliminating the need to switch between multiple programs. This seamless integration offers an easier learning curve, as you can design, simulate, and generate tool paths within one environment. In contrast, separate systems require different software for design and control, which might be more complex for newcomers. Integrated solutions are ideal for beginners as they centralize all functionalities in one accessible interface.

What learning resources are available with CNC software for beginners?

CNC software for beginners typically has many learning resources to help you get started. These include built-in tutorials, video guides, detailed documentation, and active community forums where users share tips and solutions. Many software packages also offer webinars and online courses to simplify learning. Such support ensures that you can access step-by-step instructions and troubleshooting advice, making it easier to confidently progress from simple designs to more complex machining tasks.

Can CNC software for beginners handle complex projects over time?

Many CNC software for beginners are designed to grow with your skill level. While they initially focus on simple 2D or 2.5D projects, several programs offer scalable features that allow you to tackle more complex designs as you gain experience. Upgrading to pro versions or integrating additional modules often unlocks enhanced functionalities, such as 3D modelling and advanced tool path options. This scalability means that even if you start with basic projects, the same software can support increasingly intricate endeavours as your proficiency improves.

How important is community support when selecting CNC software for beginners?

Community support is crucial for beginners when starting with CNC software. A vibrant community offers invaluable resources, including forums, social media groups, and shared tutorials to help you troubleshoot problems and learn advanced techniques. Peer advice and real-world success stories make the learning process less intimidating. Software with robust community backing often evolves more rapidly with user feedback, ensuring that as you progress, the software adapts to meet your growing needs in CNC machining.

What factors influence the cost of CNC software for beginners?

CNC software costs for beginners vary based on features, support, and overall functionality. Many programs offer free or subscription-based options, which include essential CAD/CAM capabilities for simple projects. Paid versions provide advanced features, better customer support, and regular updates. Consider factors such as the scope of your projects, compatibility with your CNC hardware, and future scalability when evaluating costs. Starting with free or low-cost software allows you to build foundational skills before investing in more advanced, professional solutions.