Top 9 Best CAD Software for Woodworking in 2025

9 Best CAD Software for Woodworking: Woodworking has long been a cherished craft, one that transforms raw timber into timeless works of art and functional masterpieces. Traditionally, you relied on hand-drawn sketches, careful measurements, and years of experience to bring your designs to life. Yet, as technology evolves, so does the way you approach your craft.

Today, Computer-Aided Design (CAD) software stands at the forefront of this digital transformation. It bridges the gap between your creative vision and precise execution in ways that manual methods never could. Imagine designing intricate joinery details, visualizing three-dimensional renderings of your work, or seamlessly integrating your designs directly with CNC routers and laser cutters, all from your computer screen.

This guide is crafted specifically for you: the modern woodworker eager to embrace digital tools without losing the soul of traditional craftsmanship. In the following pages, you’ll uncover how CAD software can elevate your projects by enhancing precision, reducing waste, and streamlining production.

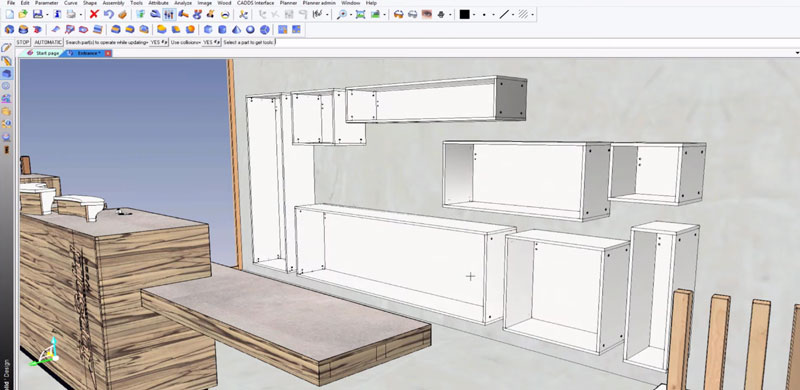

We will explore the fundamentals of CAD, discuss why woodworkers are increasingly adopting these tools, and break down the essential features you should look for in your next software purchase. Finally, we review nine of the best CAD options available from Autodesk Fusion 360 and SketchUp to AutoCAD, Shapr3D, SketchList 3D, SOLIDWORKS, Easy Woodworking Design, Autodesk Inventor, and Onshape so you can make an informed decision tailored to your unique needs.

By the end of this journey, you’ll not only understand the transformative power of CAD software but also be prepared to integrate it into your workshop with confidence. Let’s dive in and discover how embracing digital design can revolutionize your woodworking, enhance your creativity, and pave the way for a new era of craftsmanship.

What Is CAD Software? A Foundation for Woodworkers

CAD (Computer-Aided Design) software represents the digital evolution of drafting and design. This tool empowers you to transform conceptual sketches into detailed, measurable plans before any physical work begins. At its core, CAD replaces traditional drafting with precise, scalable digital models that you can modify, analyze, and refine with ease.

The Evolution of Design

Before CAD, woodworkers painstakingly transferred ideas onto paper using pencils, scaled rulers, and erasers. Each design was an individual artwork that required redrawing for any modification.

Today, CAD software lets you create 2D drawings and 3D models that automatically adjust to parameter changes so that a single tweak can update the entire design. The transition from manual to digital is not a matter of replacing traditional skills but rather enhancing them by reducing errors and ensuring consistency.

How CAD Transforms Your Workflow

With CAD, you enter a digital world where:

- Visualization is vivid: You can view your project in three dimensions, rotate models, and inspect every angle.

- Precision reigns: Input exact measurements and see real-time modifications, which help you reduce costly mistakes.

- Documentation becomes dynamic: Detailed blueprints, material lists, and assembly instructions are generated automatically.

- Collaboration is effortless: Easily share digital designs with clients, colleagues, and CNC operators, ensuring clear communication throughout every phase of the project.

The benefits of using CAD software extend beyond simple design. This technology has revolutionized workflows in industries ranging from automotive and aerospace to architecture and biomedical engineering. Its flexibility has made it a must-have in woodworking, where precision and artistic detail are paramount.

As a woodworker, adopting CAD software means you’re not abandoning traditional values; you are enriching them with tools that help preserve quality while dramatically increasing efficiency. By embracing CAD, you align your craft with modern innovation while upholding the artistry that woodworkers have celebrated for centuries.

Why Woodworkers Are Turning to CAD: Benefits and Applications

In today’s competitive market, woodworkers face the dual challenge of maintaining traditional craftsmanship while meeting high standards of precision and efficiency. CAD software addresses these challenges head-on by offering tools that enhance every aspect of the woodworking process.

Enhanced Precision and Accuracy

When you design digitally, you eliminate the guesswork that often accompanies manual drafting. CAD allows you to input exact measurements and generate detailed drawings that accurately reflect your intended dimensions. This means your pieces, whether they are bespoke cabinets, intricate joinery details, or custom furniture, fit together perfectly the first time, reducing waste and minimizing error.

Improved Visualization and Design Flexibility

Imagine being able to see a photorealistic rendering of your work before you even touch the wood. CAD software enables you to view your design in 3D, experiment with different styles, and make adjustments on the fly.

With virtual models, you can explore various textures, colors, and finishing details that were once only imaginable. This ability to visualize your final product in a virtual space allows you to refine your ideas. It ensures that every project aligns with your creative vision.

Integration with CNC and Automation Technologies

One of the most transformative benefits of CAD is its seamless integration with CNC (Computer Numerical Control) machinery. By designing your projects digitally, you can directly generate NC (Numerical Control) programs and tool paths that guide CNC machines to cut, carve, and shape your woodwork with extraordinary precision. This integration not only speeds up production but also ensures consistency and quality in every piece you craft.

Streamlined Communication and Collaboration

CAD software is a powerful facilitator of collaboration. Whether you’re working solo or coordinating with a team, digital files can be shared effortlessly. You can send your designs to CNC technicians, suppliers, or clients without misinterpretation, ensuring that everyone is aligned on the project’s specifications. This transparency minimizes miscommunication and helps avoid costly revisions down the line.

Reduction in Cost and Waste

With accurate cut lists and material estimations provided by CAD, you can plan your projects more efficiently. Understanding exactly how much material you need and optimizing the cutting layout reduces waste, saves costs, and streamlines project management. Digital design replaces trial-and-error approaches with scientifically driven methods that prioritize resource conservation.

Real-World Applications

From detailed joinery work like dovetails and mortise-and-tenon joints to complex cabinetry and furniture design, CAD software plays an indispensable role. You can plan assembly processes, generate blueprints, and even simulate stress tests on your designs to ensure structural integrity. The versatility of CAD makes it applicable not only to large commercial projects but also to artisanal, custom pieces that require a personal touch.

In short, adopting CAD software in your woodworking practice means embracing a future where enhanced precision, creative exploration, and operational efficiency combine to deliver superior results in every project. As traditional methods blend with digital innovation, you unlock a new level of craftsmanship that meets the demands of modern consumers and elevates your work to unprecedented heights.

Key Features to Look for in CAD Software for Woodworking

Before you choose your CAD software, it is crucial to understand what features will optimize your workflow and meet your specific woodworking needs. Here are the key components to consider:

Intuitive User Interface

- Ease of Navigation: The software should have a clean, logical layout that makes it simple to access tools and commands.

- Minimal Learning Curve: A well-designed interface reduces frustration, allowing you to focus on creativity.

2D and 3D Modeling Capabilities

- 2D Detailed Drawings: Essential for blueprints and assembly instructions.

- 3D Visualization: See a realistic model of your project, rotate it, and examine details from every perspective.

Precision and Measurement Tools

- Exact Dimension Input: Ensure every joint and angle is accurately rendered.

- Scale Management: Tools to handle different project sizes seamlessly.

Joinery and Assembly Design Tools

- Pre-built Libraries: Access to common woodworking joints (dovetails, mortise, and tenon, etc.).

- Custom Joinery Options: Flexibility to design unique connections that meet your project’s needs.

Material Estimation and Optimization

- Cut List Generation: Automatically prepare detailed lists of materials required.

- Waste Minimization: Tools to optimize material usage and reduce scrap.

CNC Integration

- File Export Compatibility: Export designs directly in formats (e.g., DXF, G-code) that are compatible with CNC machines.

- Toolpath Generation: Automate the translation of drawings into CNC instructions.

Parametric and Direct Modeling

- Dynamic Updates: Modify one parameter, and the entire design updates automatically.

- Rapid Iterations: Easily experiment with design variations without starting from scratch.

Comprehensive Support and Tutorials

- Learning Resources: Availability of video tutorials, documentation, and community forums.

- Customer Service: Access to robust support channels to help you troubleshoot and learn.

By ensuring your CAD software includes these vital features, you guarantee a smoother transition from traditional drafting to a digital workflow. The right tool will enhance your creative process, improve efficiency, and ultimately lead to higher-quality finished projects.

Top 9 Best CAD Software for Woodworking in 2025

Below are comprehensive, in-depth reviews of the nine best CAD software options tailored for woodworking. we have talked about their key features, pros and cons for the software.

1. Autodesk Fusion 360

Autodesk Fusion 360 is a state-of-the-art, cloud-based CAD/CAM solution integrating design, simulation, and manufacturing in one unified platform. It offers powerful parametric and freeform modeling tools that let you tackle complex woodworking projects with confidence.

Fusion 360 provides real-time collaboration, robust version control, and direct CNC integration, making it an ideal solution for custom furniture design and detailed joinery work. Its comprehensive toolset is accessible to both beginners and experts, streamlining your workflow from concept to production.

Key Features:

- Advanced parametric and freeform modeling tools

- Integrated simulation and CAM functionalities

- Direct CNC compatibility with toolpath generation

- Cloud-based collaboration and version control system

- Extensive library of joinery and assembly design elements

Pros:

- Seamless integration between design and manufacturing

- Highly flexible toolset for both simple and complex projects

- Extensive online tutorials and active community support

Cons:

- The steep learning curve for advanced features

- Native cut list functionality requires third-party add-ins

- Subscription-based pricing model may be costly for some users

2. SketchUp

SketchUp is a pioneering 3D modeling software celebrated for its user-friendly interface and intuitive design environment. With a vast library of extensions and pre-made 3D models, SketchUp lets you create detailed, realistic renderings of your woodworking projects.

Whether you are planning intricate joinery or visualizing entire furniture pieces, its simplicity and versatility make it a favorite among woodworkers. Available in both free web-based and paid desktop versions, SketchUp scales easily to meet evolving design needs without compromising on quality.

Key Features:

- Intuitive 3D modeling with easy-to-use drawing tools

- Extensive library of plugins, models, and pre-built extensions

- Simple interface ideal for beginners and intermediate users

- Options for web-based, desktop, and mobile design workflows

- Ability to create detailed shop drawings and cut lists with extensions

Pros:

- The easy learning curve with abundant online tutorials

- Highly visual and creative design environment

- Flexible platform with scalable features for various projects

Cons:

- Limited advanced CNC integration features

- The free version offers only core functionalities

- May require additional extensions for comprehensive woodworking workflows

3. AutoCAD

AutoCAD stands as an industry-standard CAD software revered for its high precision in 2D drafting and technical detailing. Although primarily focused on intricate 2D design, it also delivers robust 3D modeling capabilities, albeit with a steeper learning curve.

Tailored to meet the rigorous demands of technical projects, AutoCAD’s vast library of tools and customizable plugins enables you to produce highly accurate blueprints and plans. While its interface is geared toward professional users, its reliability and feature richness make it a powerful option for sophisticated woodworking projects.

Key Features:

- Precise 2D drafting tools for detailed technical drawings

- Comprehensive 3D modeling capabilities for visualization

- Customizable interface with extensive plugin support

- Advanced scaling, dimensioning, and annotation tools

- Robust automated documentation and blueprint generation

Pros:

- Industry-leading accuracy and reliability

- Versatile tools for both 2D drafting and 3D modeling

- Highly customizable with a wide variety of add-ons

Cons:

- The steep learning curve is not ideal for beginners

- High subscription costs may limit small business adoption

- Overwhelming set of features for basic woodworking projects

4. Shapr3D

Shapr3D is an award-winning, touch-based 3D modeling software explicitly designed for modern devices like the iPad, Mac, and Windows. Its intuitive, stylus-friendly interface makes it easy to sketch, extrude, and manipulate solid objects, rendering it perfect for designing detailed woodworking components.

Shapr3D excels in translating sketch ideas into precise 3D models, which is ideal for planning joinery and assembling digital boards. With a blend of simplicity and power, it caters to both quick revisions on the go and more detailed project workflows.

Key Features:

- Touch and stylus-friendly interface for natural drawing input

- Rapid solid modeling with intuitive extrude and subtract functions

- Robust component management through folder organization

- Cross-platform compatibility with seamless file sharing

- Responsive performance allows for quick design iterations

Pros:

- Outstanding ease of use on mobile and desktop devices

- Fast performance ideal for on-the-go design work

- Intuitive modeling tools that reduce design time significantly

Cons:

- The free version limits complexity and export options

- Some advanced tools, like rotation manipulation, require practice

- Lacks certain high-end features needed for very complex projects

5. SketchList 3D

SketchList 3D is uniquely crafted for the woodworking community and is designed to simplify the entire process from drafting to production. Focusing on the specific needs of woodworkers, it allows you to generate virtual boards, design intricate joinery, and produce accurate cut lists seamlessly.

The software’s intuitive workflow reduces the learning curve, making it accessible to beginners while offering enough depth for experts. With built-in tools for material estimation and DXF export for CNC integration, SketchList 3D optimizes your workflow and ensures precision in every project.

Key Features:

- Dedicated tools for virtual board management and joinery design

- Automated material estimation and cut list generation

- Support for DXF export, enabling smooth CNC integration

- Comprehensive library of woodworking-specific components

- Intuitive interface that simplifies design for novices

Pros:

- Specifically tailored for the demands of woodworking

- Streamlines joinery and material planning processes

- User-friendly design that minimizes training time

Cons:

- Advanced 3D modeling features are less robust than general CAD tools

- Customization options for unique projects are somewhat limited

- Integration with non-woodworking systems can be challenging

6. SOLIDWORKS (for Makers/Professionals)

SOLIDWORKS is a professional-grade 3D CAD software celebrated for its powerful modeling, simulation, and documentation tools. Widely used in diverse industries, it offers robust parametric design and assembly management features that translate effectively to woodworking.

Specialized versions like SOLIDWORKS for Makers provide accessible entry points into the software’s advanced capabilities without the high cost of full professional licenses. With automated cut list generation and integrated woodworking-specific plugins available, SOLIDWORKS allows you to craft detailed models that combine aesthetic appeal with engineering precision.

Key Features:

- Advanced 3D modeling with parametric and direct design capabilities

- Robust simulation and analysis tools for testing designs

- Photorealistic rendering to visualize high-end projects

- Extensive libraries for woodworking joints and hardware components

- Automated cut list and assembly documentation generation

Pros:

- Exceptionally powerful for complex, high-precision designs

- Rich set of features tailored to intricate woodworking tasks

- Strong community support and extensive learning resources

Cons:

- Professional-grade pricing can be prohibitive

- Complexity may overwhelm beginners and casual users

- Requires high-performance hardware for optimal operation

7. Easy Woodworking Design

Easy Woodworking Design is engineered for simplicity and speed, catering specifically to woodworkers who favor a straightforward, 2D design environment. It enables the rapid creation of boards, assembly drawings, and comprehensive project reports, all with minimal setup.

The software’s intuitive interface is ideal if you want to complement traditional sketch methods with digital precision. Easy Woodworking Design streamlines the design process, enabling you to execute plans and make on-the-fly adjustments swiftly; perfect for hobbyists and professionals seeking efficiency without a steep learning curve.

Key Features:

- Straightforward 2D drafting tools for fast project planning

- Automated generation of detailed cut lists and assembly reports

- Built-in dimensioning and measurement aids

- User-friendly interface tailored to traditional woodworkers

- Rapid conversion of sketches into structured digital layouts

Pros:

- Extremely accessible and easy to learn

- Fast draft conversion speeds up project turnaround

- Cost-effective option for small-scale operations

Cons:

- Lacks advanced 3D visualization capabilities

- Limited customization options for complex designs

- Does not support direct CNC integration for automated workflows

8. Autodesk Inventor

Autodesk Inventor is a professional-grade CAD tool revered for its robust 3D modeling, simulation, and detailed documentation capabilities. Initially designed for engineering and mechanical projects, it adapts exceptionally well to advanced woodworking needs when paired with specialized plugins such as Woodwork for Inventor.

This platform allows you to create intricate, high-precision assemblies and detailed bills of materials seamlessly. Although its learning curve is steeper compared to more specialized software, Inventor delivers unparalleled precision for complex woodworking projects that demand engineering finesse.

Key Features:

- Robust 3D modeling with advanced simulation tools

- Parametric design with customizable iParts and iFeatures

- Detailed bill of materials (BOM) and documentation generation

- Integration with woodworking-specific plugins for joinery and material design

- Precision tools ideal for complex structural assemblies

Pros:

- Exceptionally precise and feature-rich for advanced projects

- Ideal for professional woodworkers with engineering-level requirements

- Extensive support resources and specialized plugins are available

Cons:

- A steep learning curve may deter beginners

- High costs can be prohibitive for small workshops

- Complex interface that may overwhelm non-engineering users

9. Onshape

Onshape is a modern, cloud-based CAD platform that revolutionizes collaboration with its real-time design updates and version control. Accessible from any device with an internet connection, Onshape supports parametric modeling and a variety of standard drawing tools.

Though not exclusively designed for woodworking, its versatility makes it a solid option for managing intricate designs and collaborative projects. Onshape offers both free and premium subscription plans, making it attractive to hobbyists and professionals looking for an agile, cloud-first design solution adaptable to various project sizes.

Key Features:

- Cloud-based collaborative design platform

- Real-time updates and automatic version control

- Parametric modeling with efficient editing tools

- Accessible from any device with an internet connection

- Comprehensive documentation and community support

Pros:

- Excellent for collaborative, team-based projects

- Free version available for hobbyists and startups

- Flexible, platform-independent design environment

Cons:

- Lacks woodworking-specific libraries and joinery tools

- Advanced woodworking features may require creative workarounds.

- Dependent on constant internet access for optimal performance

Which CAD Software Is Right for You? Comparisons and Recommendations

Choosing the ideal CAD software for your woodworking projects does not have a one-size-fits-all answer. Instead, evaluate your project scope, skill level, and budget to select an option that aligns with your workflow.

Consider Your Skill Level

- Beginners: If you’re new to digital design, look for software with an intuitive interface and plenty of step-by-step tutorials. SketchUp and Shapr3D provide a gentle introduction with easy-to-grasp tools.

- Intermediate Users: With some design experience, you might prefer solutions like Autodesk Fusion 360 or SketchList 3D, which offer more advanced features without overwhelming complexity.

- Advanced Professionals: For those tackling intricate projects that require engineering precision, AutoCAD, SOLIDWORKS, or Autodesk Inventor provide robust toolsets and detailed control, albeit with steeper learning curves.

Project Requirements and Workflow

- CNC Integration: If you plan to link your designs directly with CNC machines, focus on software with direct file export options and toolpath generation features such as Fusion 360 or SketchList 3D.

- Material Optimization: To reduce waste and manage budgets, consider software with advanced cut list and material estimation features, ensuring every piece of wood is used efficiently.

- Joinery Design: For intricate joinery work, choose tools that offer pre-built libraries and specialized design tools allowing for detailed dovetails, mortise and tenon joints, and more.

Budget Considerations

- Free or Low-Cost Options: Options such as the free version of SketchUp, Shapr3D’s limited free tier, or the free tier of Onshape might be ideal for hobbyists and startups.

- Subscription vs. Perpetual Licenses: Evaluate whether a subscription-based model fits your needs better than a one-time purchase. Remember that some professional software, like AutoCAD or SOLIDWORKS, might offer robust features at a higher cost.

Ultimately, the decision should cater not only to your current requirements but also leave space for growth as you expand your capabilities. As you compare the strengths, weaknesses, and unique features of each software, you can confidently make an informed choice that optimizes both creativity and precision in your workshop.

Getting Started: Resources and Tutorials for Woodworking CAD

Embarking on the journey into digital design may seem daunting at first. Still, a vast array of learning resources and community support can ease the transition. Here are some excellent options to help you master your chosen CAD software:

Autodesk Fusion 360

- Video Series: “Fusion 360 for Woodworkers” on YouTube offers a series of tutorials tailored specifically to woodworking projects.

- Official Tutorials: Autodesk’s learning hub provides step-by-step guidance and practical projects to build your skills.

- Community Forums: Engage with a vibrant user base on discussion boards and social media groups focused on Fusion 360.

SketchUp

- Task-Oriented Guides: Explore “SketchUp Success for Woodworkers” by experienced practitioners who break down common project challenges.

- Books and eGuides: Resources like “SketchUp for Woodworkers: A Complete Illustrated Reference” deliver in-depth insights.

- Online Communities: Participate in dedicated SketchUp forums and attend webinars to share tips and best practices.

AutoCAD

- Official Documentation: Autodesk offers extensive tutorials and detailed user manuals for mastering AutoCAD’s drafting techniques.

- Third-Party Courses: Platforms like Udemy and LinkedIn Learning host comprehensive courses that focus on technical drafting for woodworking.

- User Forums: Exchange ideas and troubleshoot issues with a global community of AutoCAD professionals.

Shapr3D

- Interactive Tutorials: Directly accessible from the software, these tutorials cover everything from basic navigation to advanced modeling techniques.

- YouTube Channels: Shapr3D’s official channel features case studies, tips, and best practices for on-the-go design work.

- Customer Support: Access responsive support services that guide you through challenges and advanced features.

SketchList 3D

- Weekly Workshops: Participate in live sessions led by experts who dive into woodworking-specific design and optimization.

- Video Tutorials: Detailed, step-by-step walkthroughs cover every aspect of the software, from virtual board setup to CNC preparation.

- Resource Libraries: Gain access to a wealth of sample projects and templates to help you model your designs.

SOLIDWORKS

- MySOLIDWORKS Portal: A comprehensive hub for training modules, community forums, and certified courses.

- Instructor-Led Training: Find local workshops or online training sessions that delve into 3D modeling and simulation tailored for woodworking.

- Community Challenges: Engage in contests and projects that spur learning and innovation across a community of makers.

Easy Woodworking Design

- Demo Version: Experiment with the demo version available on the software’s website to gain firsthand experience.

- User Guides and Manuals: Download detailed user manuals that explain each tool and feature, making it easier to transition from hand-drawn plans.

- Support Forums: Some versions offer dedicated forums where users share tips, project ideas, and troubleshooting advice.

Autodesk Inventor

- Learning Paths: Autodesk’s official website provides a structured learning path complete with tutorials focused on parametric design and simulation.

- Workshops and Webinars: Look for inventor-specific sessions that concentrate on using plugins like Woodwork for Inventor.

- Online Documentation: Extensive guides detail every feature, from modeling to generating comprehensive bills of materials.

Onshape

- Learning Center: Onshape’s dedicated Learning Center offers self-paced courses, documentation, and interactive tutorials.

- Community Blogs: Get insights from experienced users via blogs, real-world case studies, and tips shared in community forums.

- Video Tutorials: Free video tutorials on YouTube detail everything from basic sketching to advanced assembly techniques.

By diving into these resources, you can build proficiency at your own pace while gaining insights from experts and peers alike. With practice, you’ll find that mastering digital design not only increases your technical skill set but also enhances the creativity and precision you bring to every woodworking project.

Future Trends in CAD for Woodworking

As digital technologies continue to evolve, the future of CAD in woodworking promises even more significant innovations and efficiencies. Here are a few trends to watch:

Integration with Augmented Reality (AR)

- Real-Time Visualization: Imagine overlaying a digital model of your design onto physical materials before cutting begins.

- Interactive Collaboration: AR tools allow you to interact with your 3D models in a physical space, enhancing client presentations and on-site modifications.

Improved Cloud Collaboration

- Global Teams: Cloud-based solutions will further enable real-time collaboration among team members located anywhere in the world.

- Data-Driven Design: Access to shared libraries and collaborative platforms will allow continuous refinement and innovation.

Advanced Simulation and Analysis

- Stress Testing: Future CAD tools could integrate more robust simulation features to predict material behavior under real-world conditions.

- Sustainability Modeling: Tools that help optimize designs for minimal waste and environmental efficiency are on the horizon.

Enhanced CNC and Robotics Integration

- Seamless Production: As CAD software evolves, enhanced integration with CNC machinery and robotic systems will further bridge the gap from digital design to physical production.

- Automated Adjustments: Systems that automatically adjust designs based on material imperfections or tool wear may become common.

These emerging trends signal a future where your workshop is even more connected, efficient, and innovative. Staying informed and adaptable will allow you to harness the full potential of these advancements as they become part of your daily process.

Conclusion

The digital revolution in woodworking is here, and CAD software stands at its forefront. Embracing digital design transforms how you approach every project, from the precision of detailed measurements and intricate joinery to the efficiency of automated material optimization and CNC integration. By adopting a CAD tool, you not only reduce errors and streamline production but also unlock new levels of creativity and adaptability in your craft.

As you evaluate your needs, whether you’re a beginner looking for user-friendly tools or a seasoned professional seeking advanced simulation and documentation, you’ll find that each CAD software reviewed in this guide brings something unique to the table. When you integrate these digital solutions into your workflow, you ensure that every design is a harmonious blend of traditional craftsmanship and modern technology.

Now is the time to invest in your future. With the wealth of resources, tutorials, and community support available, you can quickly build new skills and transform the way you work. Embrace the digital workshop, and let CAD software be the partner that elevates your woodworking practice to unprecedented heights. Every line you draw, every joint you perfect, and every project you complete will bear the hallmark of precision and innovation.

Are you ready to revolutionize your woodworking practice with CAD software? Subscribe to our newsletter for the latest tips, tutorials, and trends in digital design. Please share your experiences in the comments and join our community of forward-thinking woodworkers as we transform traditional craftsmanship into modern masterpieces. Don’t miss out; your journey to precision and innovation starts today!

Frequently Asked Questions

What is CAD software for woodworking?

CAD software for woodworking is an advanced digital tool that enables you to create, edit, and simulate detailed designs with high precision. It converts traditional hand-drawn sketches into accurate 2D and realistic 3D models. This transformation allows for clear visualization of joinery, precise measurements, and efficient material planning. By using CAD software for woodworking, you can reduce errors, streamline design workflows, and integrate seamlessly with CNC equipment to bring your creative ideas to life.

What are the advantages of using CAD software for woodworking?

Using CAD software for woodworking offers multiple advantages. It enhances design precision and allows you to experiment with intricate 3D models before cutting any material. With features like automated cut lists and material estimation, you significantly reduce waste and save time. This digital tool also streamlines collaboration by providing clear, shareable designs that communicate exact dimensions, ensuring fewer mistakes during production. Overall, CAD software for woodworking empowers you to optimize your creative workflow and achieve consistently high-quality results.

Which CAD software options are best for woodworking?

The best CAD software for woodworking includes a variety of platforms designed to meet different needs. Among the top choices are Autodesk Fusion 360, SketchUp, AutoCAD, Shapr3D, SketchList 3D, SOLIDWORKS, Easy Woodworking Design, Autodesk Inventor, and Onshape. Each option offers unique features, from intuitive interfaces for beginners to advanced tools for precise joinery and CNC integration. This ensures that every woodworker can find a solution tailored to their skills, project complexity, and budget.

How does CAD software for woodworking integrate with CNC machines?

CAD software for woodworking integrates with CNC machines by allowing you to export precise digital designs in formats like DXF or G-code. These files provide accurate instructions for CNC routers and laser cutters, ensuring that each cut matches your design specifications exactly. By moving from digital creation to automated manufacturing, you reduce manual errors and increase production efficiency. This seamless link efficiently bridges creative design and the physical crafting process, making CAD software for woodworking essential for modern, automated operations.

What key features should I look for in CAD software for woodworking?

When selecting CAD software for woodworking, search for essential features such as robust 2D drafting and 3D modeling tools, precise measurement functions, and an intuitive user interface. Additional key elements include specialized joinery design tools, automated cut list generation, and compatibility with CNC machines. These features help you translate complex ideas into accurate digital representations while optimizing material usage. Ultimately, the right CAD software for woodworking should balance creative flexibility with operational efficiency and ease of use.

How user-friendly is CAD software for woodworking programs?

User-friendliness in CAD software for woodworking varies by platform, with many modern options designed for ease of use. Programs such as SketchUp and Shapr3D offer intuitive, simplified interfaces and a wealth of tutorials, making it easy for beginners to transition from paper sketches to digital models. Even the more advanced tools strive to maintain an accessible design through customizable presets and guided workflows. Overall, the right CAD software for woodworking ensures that every user, regardless of experience, can confidently create and modify precise designs.

Are there free versions of CAD software for woodworking available?

Yes, several free versions and trial options exist within CAD software for woodworking. Many popular platforms, like SketchUp and Onshape, offer free tiers that include essential tools for creating accurate 2D and 3D models. These versions enable beginners and hobbyists to explore digital design without initial high costs. As your needs grow or you require advanced features, you can upgrade to paid versions. Free options act as a great starting point, allowing you to gradually invest in more sophisticated CAD software for woodworking as your skills develop.

How can CAD software for woodworking improve collaboration on projects?

CAD software for woodworking significantly improves collaboration by enabling you to share detailed digital designs with clients, team members, and CNC operators. Features like real-time updates, cloud storage, and version control ensure that everyone involved can review and comment on the project consistently. This transparent communication reduces misunderstandings and speeds up the revision process, ultimately leading to better project outcomes. With CAD software for woodworking, collaborative design becomes a streamlined process, enhancing accuracy and efficiency across the entire project lifecycle.

What role does CAD software for woodworking play in material optimization?

Material optimization is a critical advantage of using CAD software for woodworking. By creating detailed digital models, you can generate precise cut lists and material orders, which reduce waste and cut costs. The software allows you to plan each element carefully, from joinery configurations to board placements, ensuring that every piece of material is utilized efficiently. This systematic approach helps conserve resources and streamlines production. Therefore, adopting CAD software for woodworking leads to more economical, environmentally friendly projects with superior accuracy.

What resources are available to help me learn CAD software for woodworking?

There is a wide range of resources for learning CAD software for woodworking. Many programs offer comprehensive tutorials, user guides, and video lessons to help you master everything from basic sketches to advanced parametric designs. Online communities, forums, and webinars provide additional peer support and practical tips. Whether you choose Autodesk Fusion 360’s extensive learning hub or SketchUp’s task-specific help guides, these resources ensure that you can develop the skills needed to integrate CAD effectively into your woodworking practice while continuously improving your workflow.